Diffusion Soldering

Introduction. Diffusion soldering is a new environmental friendly method of bonding materials. Low temperature diffusion soldering is a technique that combines the characteristics of conventional soldering and diffusion welding. The diffusion soldering process is based on the reaction between a thin layer of low-melting metal or alloy and the bonded material that produces high-melting intermetallic phases. The formed connection shows durability up to the melting temperature of the resulting intermetallic phase. It allows the formation of solders exhibiting thermal and mechanical stability at temperatures around 2-3 times higher than the soldering temperature.

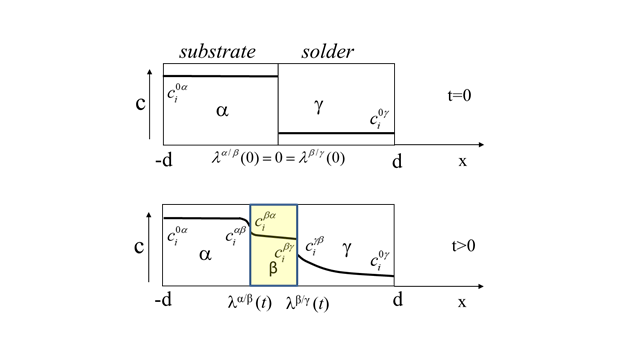

Mathematical model. The model of layer growth driven by the reactive diffusion in multi-component systems with a moving boundary was developed. The model is time-dependent (dynamic) and does not use simplifications, such as flux constancy. The general form of the constitutive equation for the flux based on the chemical potential gradient as a thermodynamic driving force for the diffusion. The model takes into account the interaction between the fluxes of diffusing species by incorporating the convection velocity term in the mass balance equation. The movement of interphase boundaries is described by the boundary conditions of the Stefan type. The model assumes a local thermodynamic equilibrium at the phase boundaries and that the growth of intermetallic phases is controlled by the diffusion of reagents through product layers and by the reactions at the boundaries.

Numerical method. For solving the layer growth model, which from the mathematical point of view is the so-called Stefan problem, meaning that the thickness of the layers can change over time. Using the appropriate change of variables, the problem with the moving boundary had been reduced to an equivalent problem with the fixed boundary. A numerical procedure based on the method of lines was developed to solve the problem and a computer program was written that allowed to determine the evolution of the thickness of layers and the concentration profiles of components in each individual layers as a function of time.

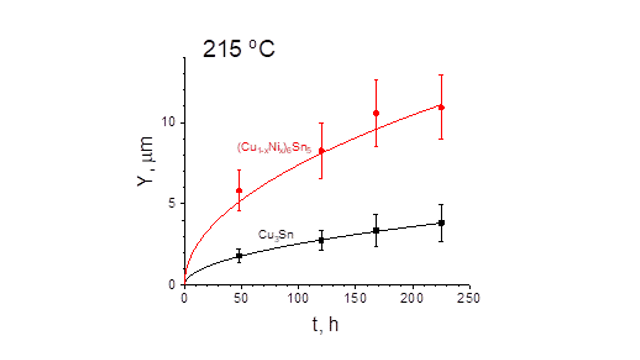

Results – mechanism and kinetics of the diffusion soldering process. Using developed model and the kinetic measurements results (thickness of layers as a function of time), the inverse problem was formulated for the problem of diffusion soldering. The soltion of the inverse method allows determination of the diffusion coefficients in the examined ternary systems: Cu/Sn-Ni, Cu-Ni/Sn, Cu/Sn-In and Ag/Sn, Ag/In. The analysis of layer growth kinetics was also carried out and the mechanism of intermetallic phase growth was determined.

Cooperation. Projects realized in cooperation with the Institute of Metallurgy and Materials Science of the Polish Academy of Sciences in Kraków:

- “Structural and kinetic characteristics of electronic joints obtained in the process of low-temperature diffusion soldering”, project no. 3TO8C02829, 2005–2008 – co-investigator.

- “Microstructural and kinetic characteristics of the phenomena occurring at the interface in diffusion couples (Sn, Nn)/Cu”, project no. 2011/03/B/ST8/06158, 2012–2016 – co-investigator.

Research papers:

- J. Wojewoda, P. Zięba, R. Onderka, R. Filipek, P. Romanów, „Growth kinetics of the intermetallics formed in diffusion soldered interconnections”, Archives of Metallurgy and Materials, 51, (2006), 345–353.

- A. Wierzbicka-Miernik, K. Miernik, J. Wojewoda-Budka, K. Szyszkiewicz, R. Filipek, L. Litynska-Dobrzyńska, A. Kodentsov, P. Zięba, „Growth kinetics of the intermetallic phases in diffusion-soldered Cu-5 at.%Ni/Sn/Cu-5 at.%Ni interconnections, Materials Chemistry and Physics, 142, (2013), 682–685.

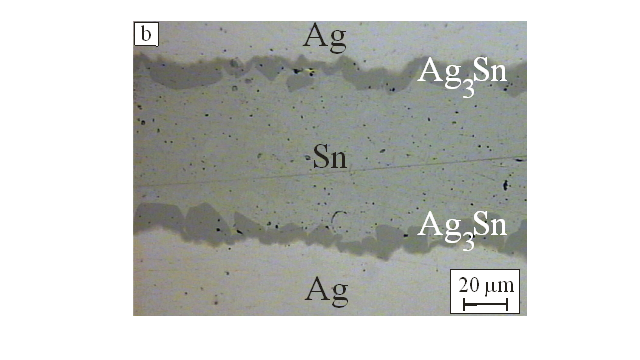

- P. Skrzyniarz, A. Sypień, J. Wojewoda-Budka, R. Filipek, P. Zięba, „Microstructure and kinetics of intermetallic phases growth in Ag/Sn/Ag joint obtained as the results of diffusion soldering”, Archives of Metallurgy and Materials, 55, (2010), 123–665.

- R. Filipek, K. Szyszkiewicz, P. Dziembaj, P. Skrzyniarz, A. Wierzbicka-Miernik, P. Zięba, “Modeling of reactive diffusion: mechanism and kinetics of the intermetallics growth in Ag/Ag interconnections”, Journal of Materials Engineering and Performance, 21, (2013), 638–647.

- A. Wierzbicka-Miernik, K. Miernik, R. Filipek, K. Szyszkiewicz, Kinetics of intermetallic phase growth and determination of diffusion coefficients in solid–solid-state reaction between Cu and (Sn+1at.%Ni) pads, J Mater Sci, 52, (2017), 10533–10544.

Contact: Prof. Robert Filipek